Batching plant Inspection Checklist

Company Name :

Date of Inspection :

Make :

Model :

Number :

Owned/Hired/Contractor :

| SN | Details |

| 1 | Batching Plant should be physically in good condition. |

| 2 | Operator cabin should be neat, clean and well maintained. |

| 3 | Conveyer should be guarded, covered and Limit switch or Pull Cord should be installed. |

| 4 | Mixing chamber should be closed. |

| 5 | Guard rail should be installed and in good condition. |

| 6 | Metal mesh should be available on aggregate and sand hoppers. |

| 7 | Staircase should be in good condition without any damage. |

| 8 | Monkey ladder should be available with cage and fall protection system. |

| 9 | All machinery of the batching plant should be installed on firm base properly. |

| 10 | Lightning arrestor should be installed. |

| 11 | Authorised and trained person only allowed to operate batching plant. |

| 12 | Fire extinguisher and first aid kit should be available in operator cabin. |

| 13 | Emergency switch and hooter should be available in working condition. |

| 14 | Aviation light should be installed and in working condition. |

| 15 | All power cables and connections should be in proper condition with earthing and grounding, MCB, ELCB, RCCB, etc as per std requirements. |

| 16 | Proper space and road provided for the stand and movement of loading, unloading trucks, other heavy equipment. |

| 17 | Whole plant should have authorised entry only. |

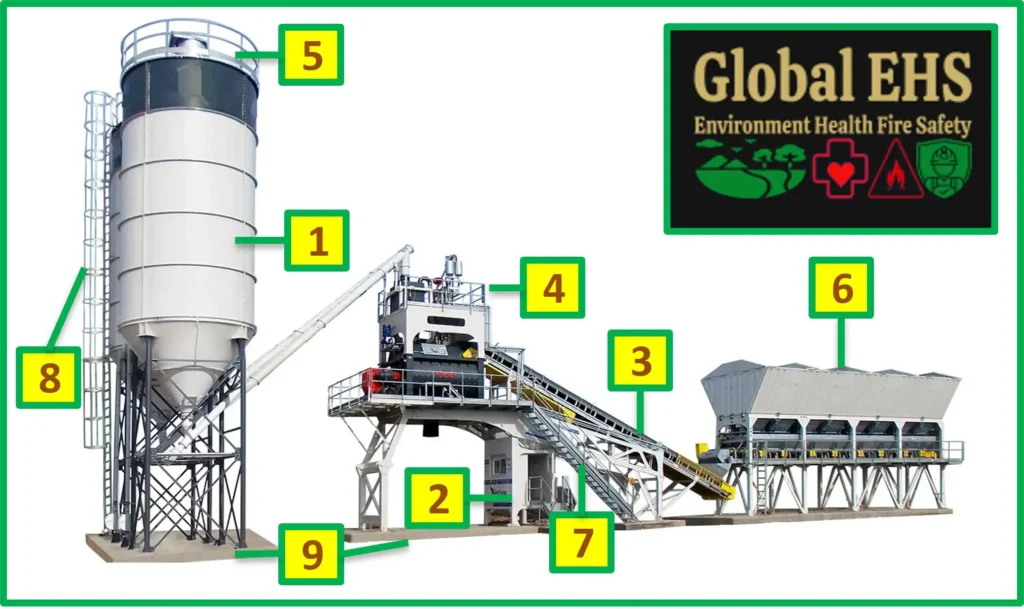

![Batching plant Safety Inspection Checklist]() Batching plant Safety Inspection Checklist

Batching plant Safety Inspection Checklist

| Inspection Done By: |

| Name: |

| Department: |

| Designation: |

| Signature: |

| Date: |

| Review Done By: |

| Name: |

| Department: |

| Designation: |

| Signature: |

| Date: |

Click here for more checklist…