Introduction

In the face of increasing fire threats and safety concerns, the role of “Spark Arrestor and Safety” has never been more crucial.

Spark arrestors serve as a vital safety mechanism, especially in industries where combustion sources are prevalent.

This blog post delves deep into understanding the significance of spark arrestors and their pivotal role in safeguarding lives, properties, and the environment.

What is a Spark Arrestor?

A spark arrestor is a specialized device designed to prevent sparks or flames from escaping combustion sources, like engines or exhaust systems.

Serving as a barrier, spark arrestors trap or extinguish sparks and hot particles before they can ignite surrounding flammable materials.

This mechanism not only prevents fires but also ensures safety and compliance with regulatory standards.

The Importance of Spark Arrestor and Safety

The significance of “Spark Arrestor and Safety” extends beyond mere fire prevention. Here’s why they are indispensable:

- Fire Prevention: By controlling sparks and flames, spark arrestors significantly reduce the risk of fires, protecting natural habitats and communities.

- Equipment Safety: Spark arrestors prevent equipment-related fires, ensuring the longevity and optimal performance of machinery and vehicles.

- Environmental Protection: By curbing fires and reducing emissions, spark arrestors contribute to environmental conservation and sustainability.

- Safety Compliance: Many jurisdictions mandate the use of spark arrestors in specific industries to adhere to safety regulations and standards.

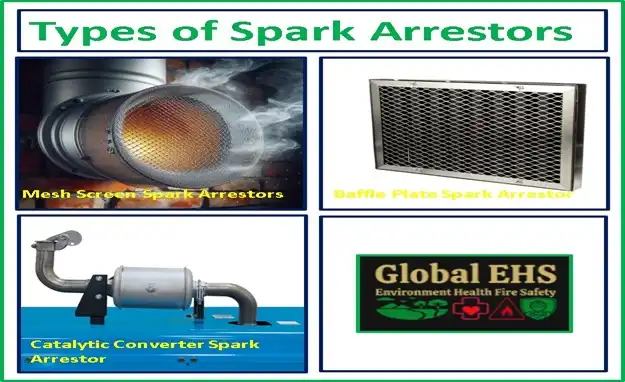

Types of Spark Arrestors

Spark arrestors come in various types, each with its unique design and functionality, some common types are given below:

- Mesh Screen Arrestors: These use a mesh screen to trap sparks and hot particles.

- Baffle Plate Arrestors: Baffle plates redirect the flow of exhaust gases, extinguishing sparks in the process.

- Catalytic Converter Arrestors: These arrestors use a catalytic process to convert harmful emissions into less harmful substances.

Understanding the different types of spark arrestors helps in selecting the most suitable one for specific applications, ensuring maximum efficiency and safety.

Maintenance and Best Practices for Spark Arrestor and Safety

Regular maintenance of spark arrestors is essential to ensure their effectiveness and longevity. Here are some best practices to follow:

- Regular Inspections: Conduct routine inspections to check for signs of wear and tear or damage.

- Cleaning: Clean the spark arrestor regularly to remove accumulated soot, debris, or blockages.

- Timely Repairs: Address any issues or damages promptly to prevent further deterioration.

- Compliance Checks: Ensure that the spark arrestor meets safety standards and regulatory requirements.

By adhering to these maintenance practices, businesses and individuals can maximize the benefits of “Spark Arrestor and Safety,” ensuring optimal performance and compliance.

Conclusion

“Spark Arrestor and Safety” play a pivotal role in fire prevention, equipment safety, and environmental protection. Understanding their importance and adhering to best practices can make a significant difference in ensuring safety, compliance, and environmental stewardship.

Whether you’re a business owner, a homeowner, or an environmental enthusiast, embracing spark arrestors and safety measures is a step towards creating a safer, healthier, and more sustainable future.