Gas Cutting Set Inspection Checklist

Company Name :

Date of Inspection :

Make :

Model :

Number :

Owned/Hired/Contractor :

Check Points for inspection of Gas Cutting Set:

| SN | Details |

| 1 | Cylinder should always be kept in trolley. |

| 2 | Always keep cylinder in upright position and secured. |

| 3 | Always ensure valve protection cap with it. |

| 4 | Regulator should be of standard and free from defect. |

| 5 | Pressure gauge should be in good condition, without any defect. |

| 6 | Hose pipe is in good condition and colour coded as per standard. |

| 7 | Joint should be tight enough and without any defect. |

| 8 | Must use Industrial clip for fitting. |

| 9 | Flash back arrestor should be provided at both end (At cylinder pressure gauge and at torch hose pipe). |

| 10 | Always use industrial type lighter (No matchbox / Commercial Lighter allowed) |

| 11 | Proper Personal Protective Equipment-PPE should be used while use for e.g., Safety Goggles, Leather Apron, Leather hand gloves, etc. |

| 12 | Torch should be in good condition, without any defect. |

| 13 | First Aid Kit and Fire Extinguisher should be available at work place. |

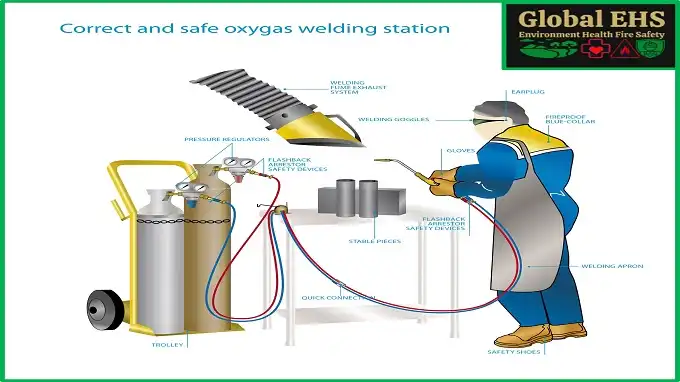

| 14 | Provide booth if required. Refer image in box for ideal Gas Cutting Station. |

| 15 | Competent person only should carry out gas cutting work. |

correct and safe oxygas welding station Global EHS

correct and safe oxygas welding station Global EHS| Inspection Done By: |

| Name: |

| Department: |

| Designation: |

| Signature: |

| Date: |

| Review Done By: |

| Name: |

| Department: |

| Designation: |

| Signature: |

| Date: |