Forklift Safety

Introduction

- Forklift is a powered industrial truck used for lifting and movement of material over short distances.

- It is also called Lift Truck, Fork Truck, fork hoist and Forklift Truck, Etc.

- It also helps person to lift and place heavy load with little effort where human can`t lift.

- It is widely used to move heavy loads in Construction, Manufacturing, Warehouses, Storage Godowns, Pharmaceuticals like industries.

Types of Forklifts based on Structure

Most popular types of Forklifts in market are:

- Warehouse forklifts.

- Site Loader.

- Counterbalance Forklift.

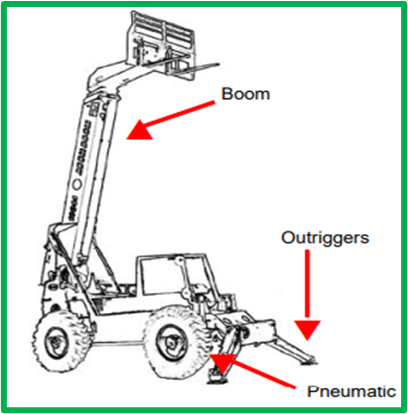

- Telehandler.

- Heavy-Duty Forklift.

- Rough Terrain Forklift.

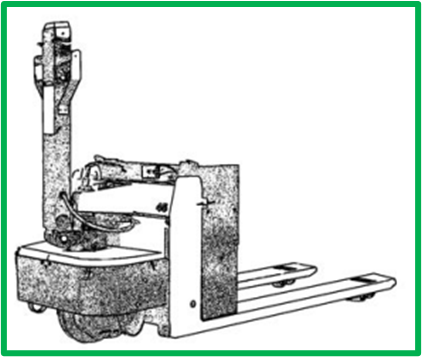

- Pallet Jack.

- Walkie Stacker.

- Order Picker.

- Reach Fork Truck.

Types of Forklifts based on fuel

- Diesel Powered.

- Electric Powered.

- Gasoline Powered.

- LP-Gas Powered.

Forklift Safety while refueling and recharging

- Park in designated while refueling and recharging area.

- Do not block emergency equipments while operating forklift.

- Make sure area is well ventilated.

- Make sure availability of fire-fighting equipments nearby while forklift refueling or recharging.

- Turn off Engine and Lights.

- Do not smoke in the area while refueling or recharging.

- Do not spill fuel during refueling or recharging.

- Use only approved cans in case of refueling.

- For LP, Shut off valves while refueling.

- Make sure availability of Spill kit while refueling.

Forklift Operations Safety or Control Measures

- Always follow the manufacturer’s instructions while using forklift.

- Only trained and certified operators allowed to operate Forklift.

- Ensure operators are trained on types of trucks they are going to use.

- Keep forklift neat and clean condition, free of excess oil and grease.

- Always wear a seatbelt while operating Forklift.

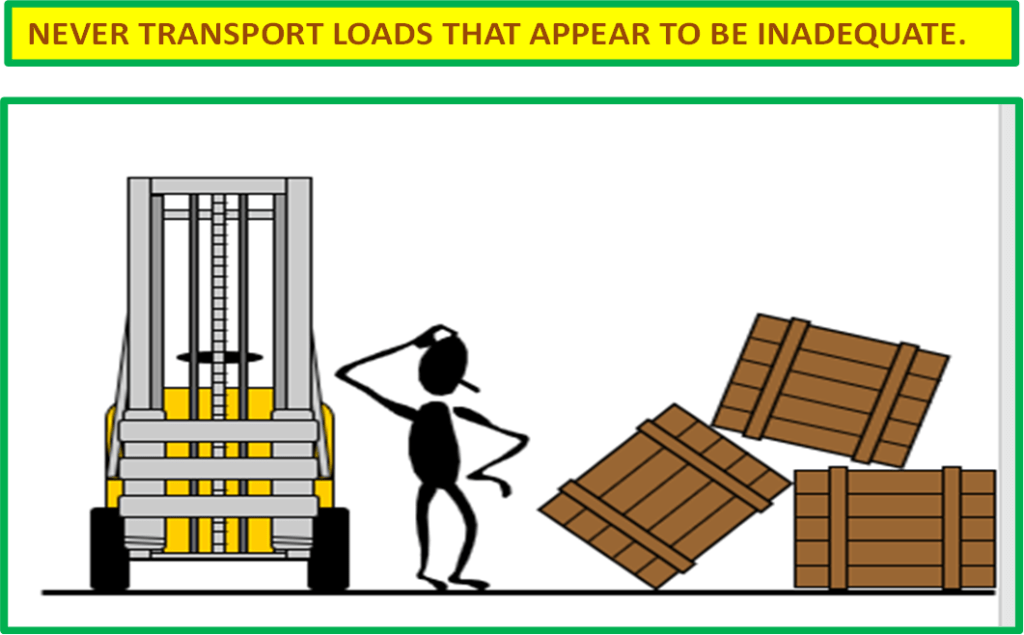

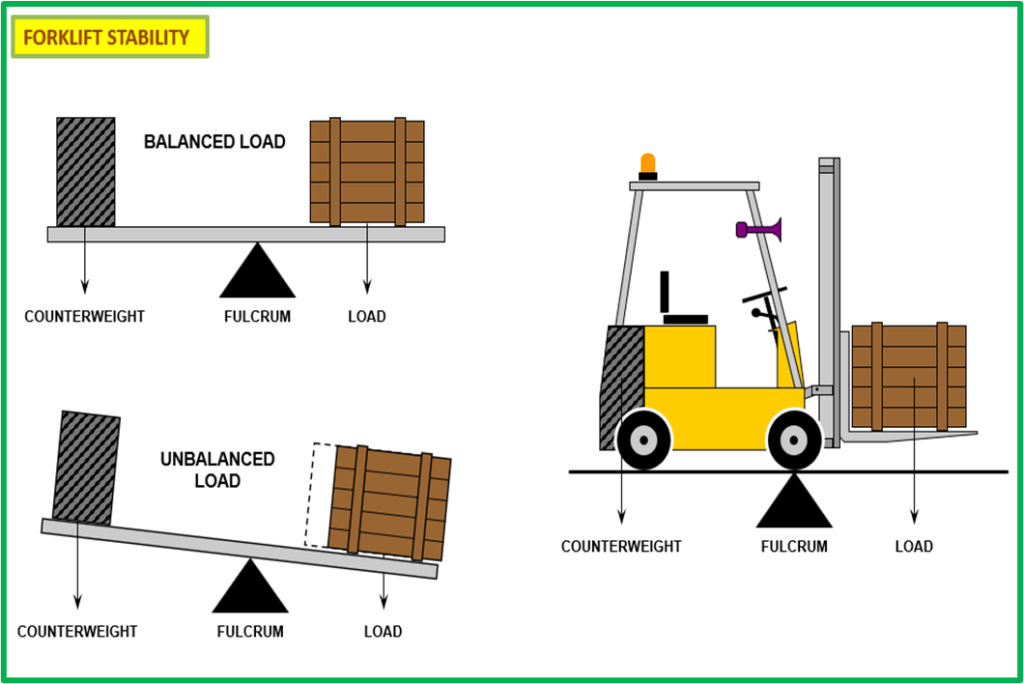

- Never exceed the rated load and ensure it is stable and balanced.

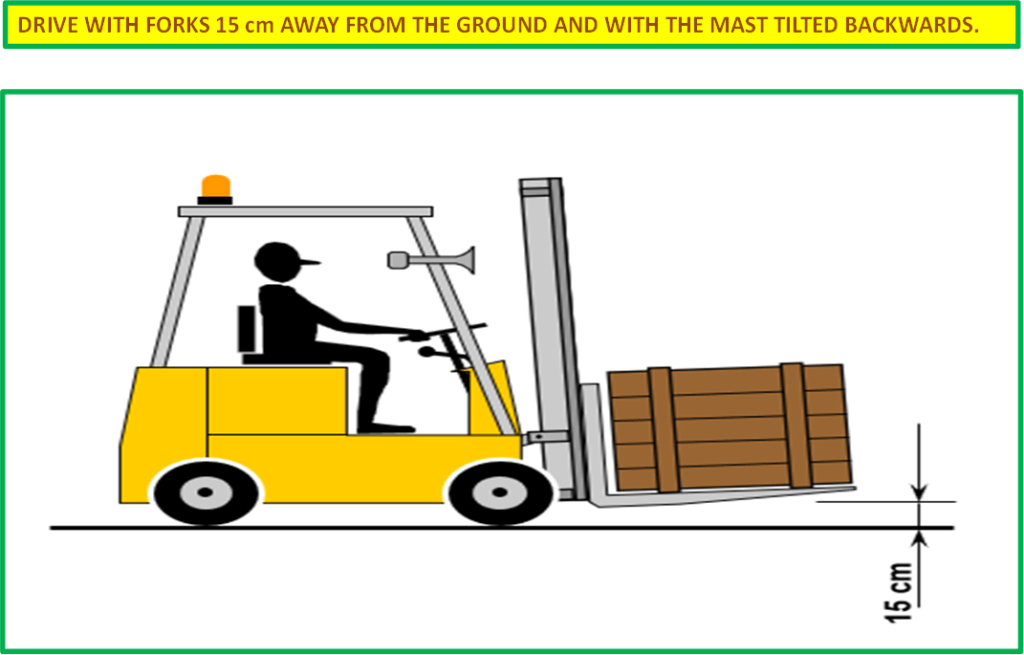

- Do not raise or lower the load while traveling.

- Keep a safe distance from platform and ramp edges.

- Be aware of other vehicles in the work area.

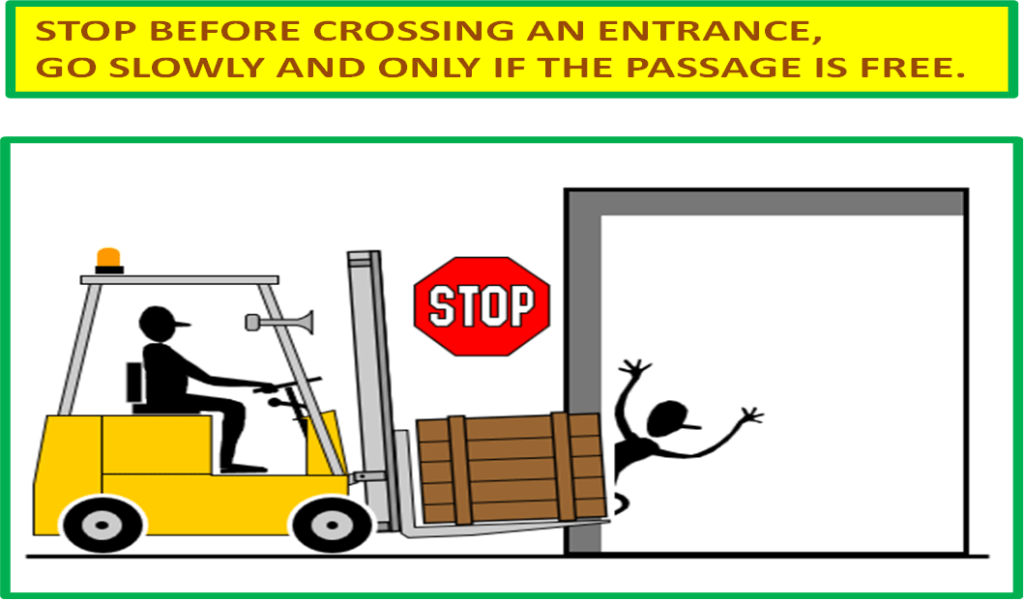

- Have clear visibility of the work area and ensure you have enough clearance when raising, loading, and operating a forklift.

- Use proper footing and the handhold, if available, when entering the lift.

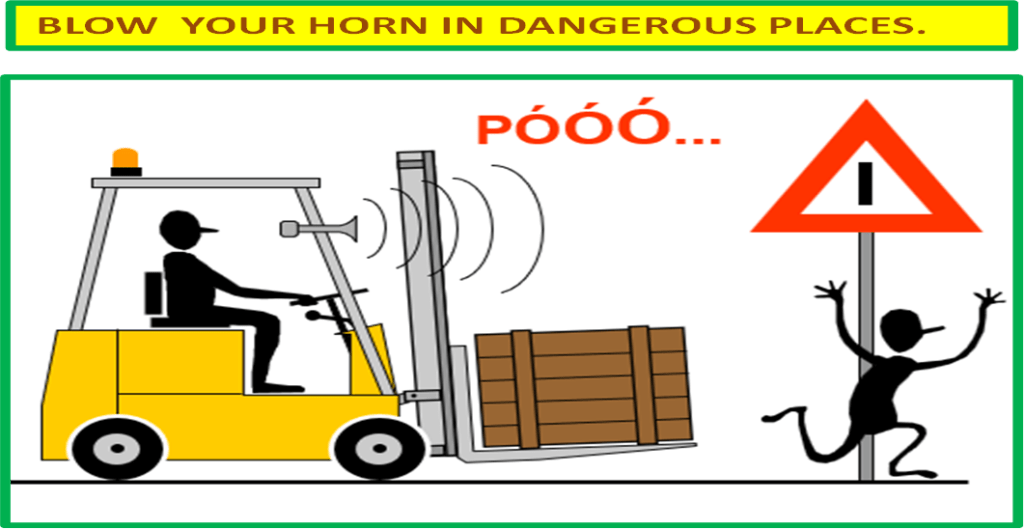

- Use horns at cross aisles and obstructed areas.

- Watch for pedestrians and observe the speed limit while driving forklifts.

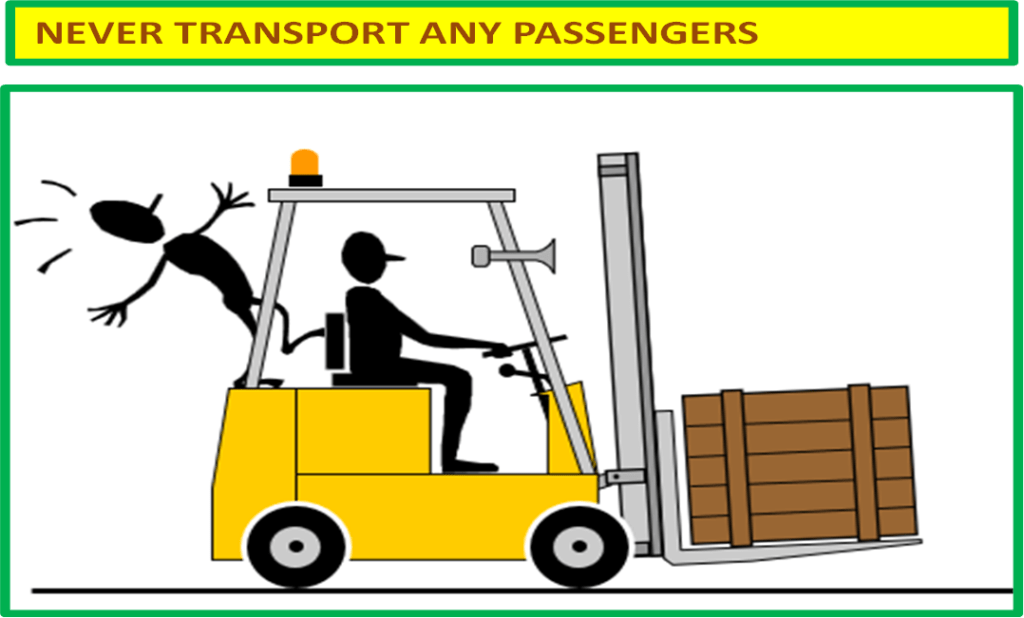

- Do not give rides or use the forks to lift people.

- Drive with forks 15 cm away from the ground and mast tilted backwards.

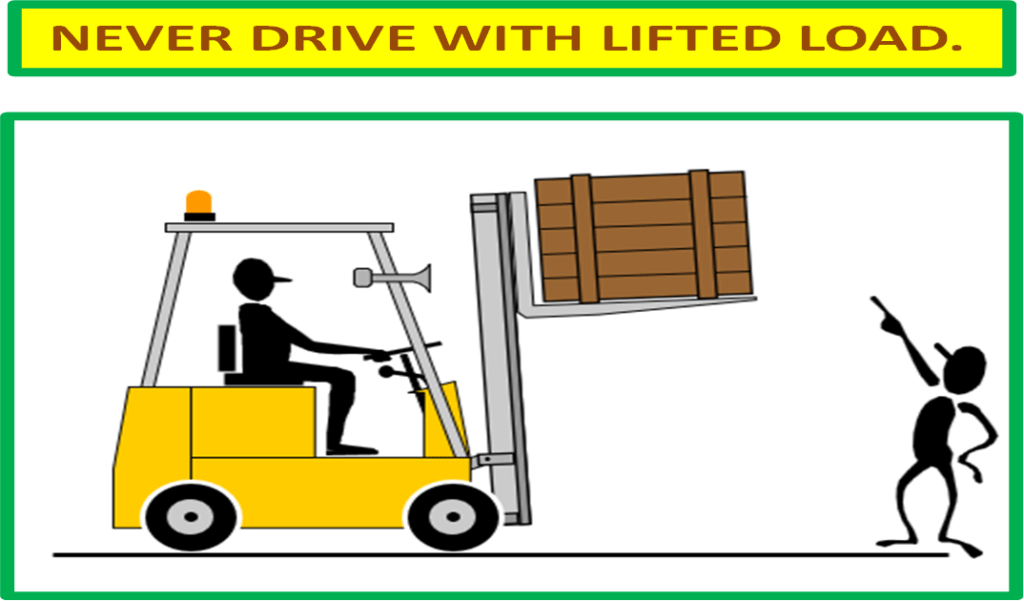

- Never Drive when load is lifted.

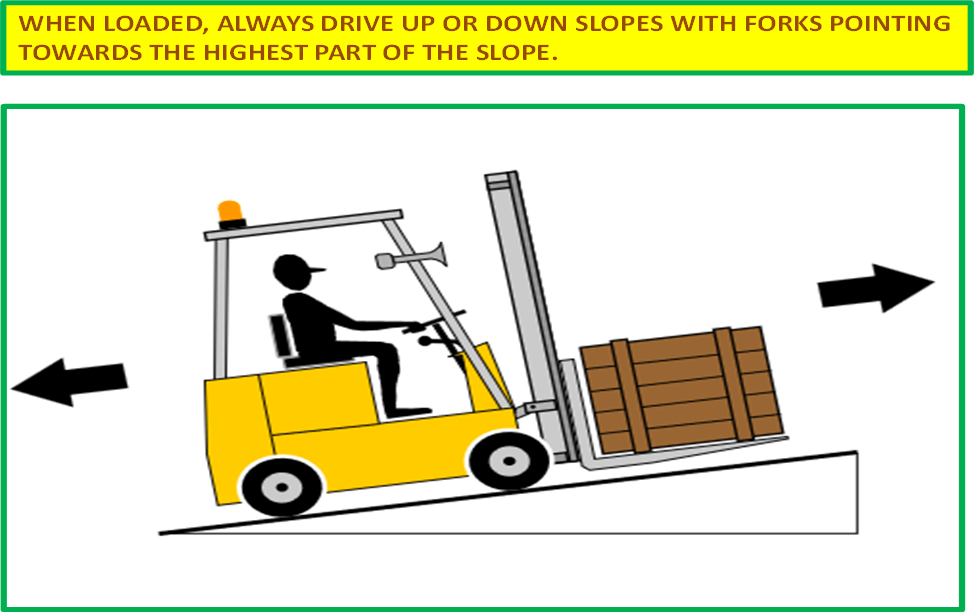

- When loaded, always drive up or down slope with forks pointing towards the highest part of the slope.

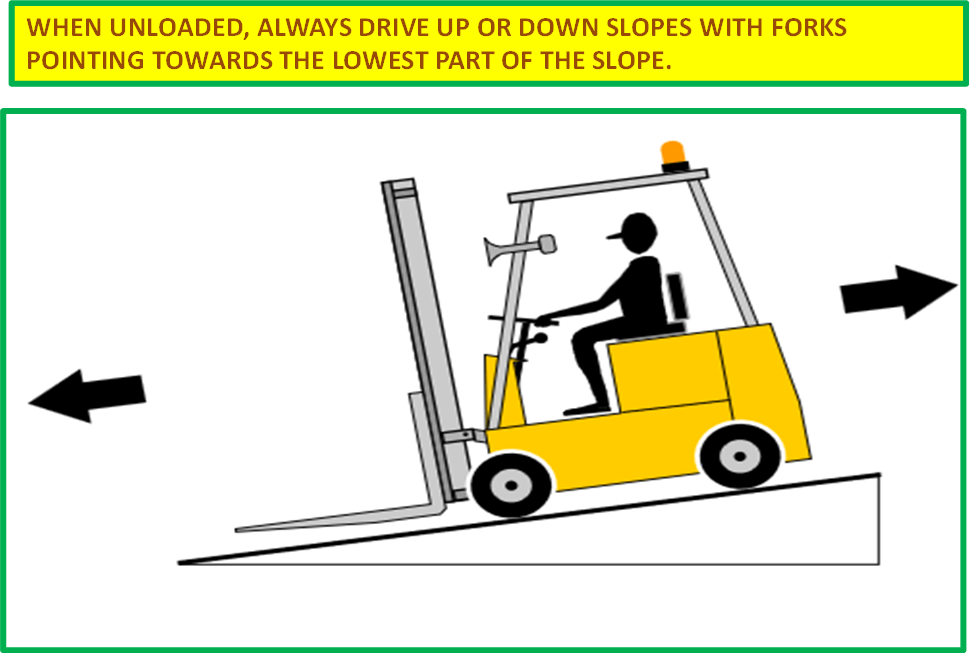

- When unloaded, always drive up or down slopes with forks pointing towards the lowest part of the slope.

- Always drive slowly, especially driving down a slope.

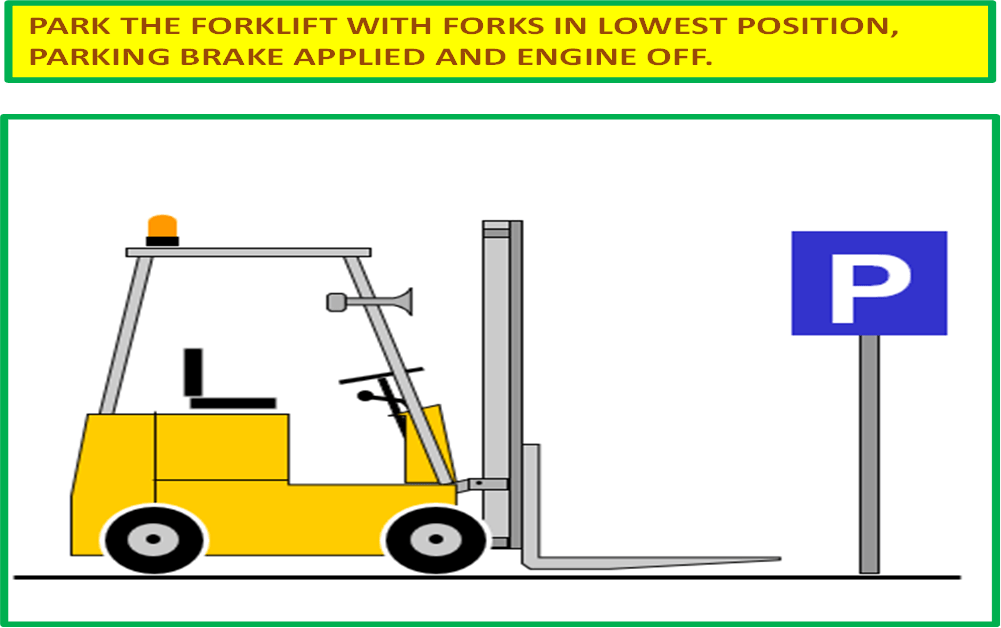

- Always park forklift in designated parking area with fork in lowered position, parking brake applied and engine off.

- Never park forklift on slope.

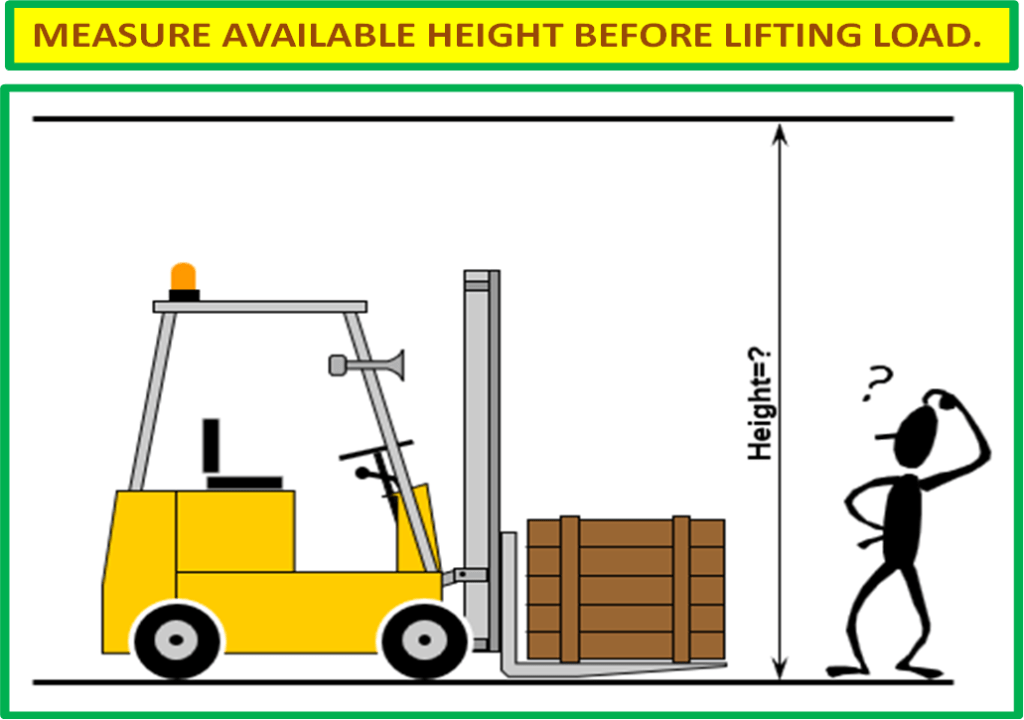

- Measure available height before lifting load,

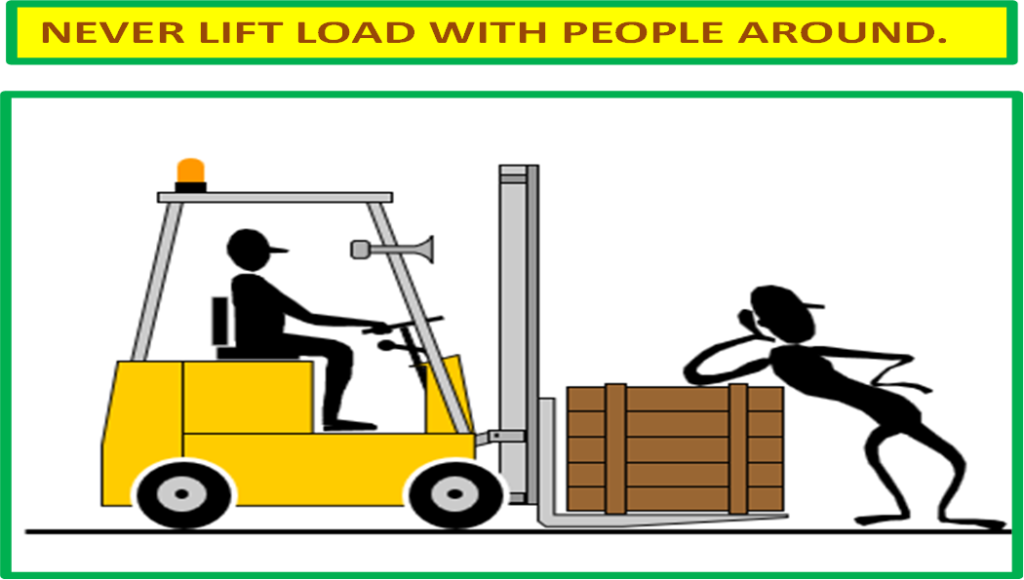

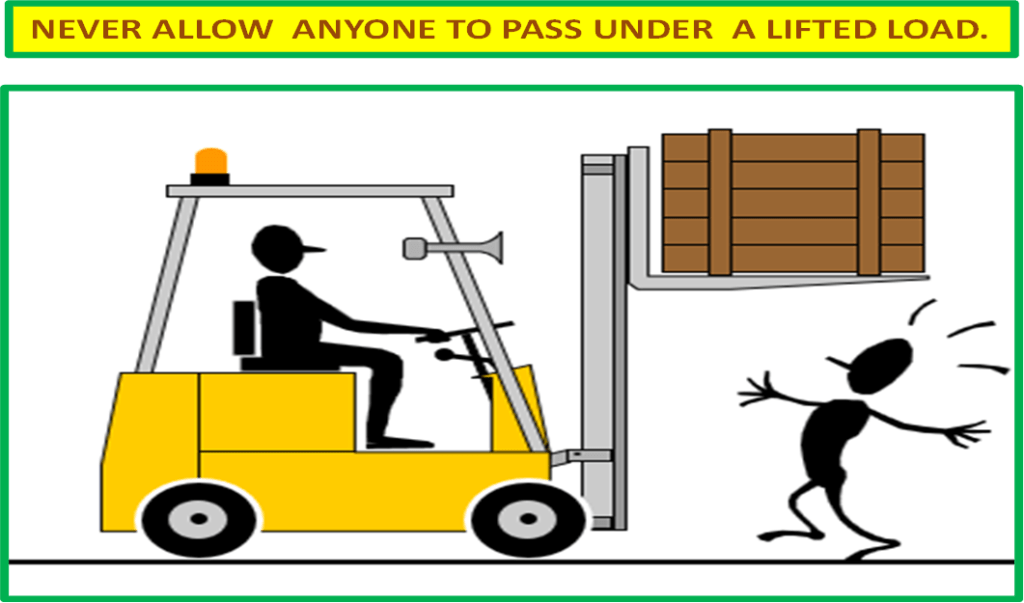

- While lifting load ensure nobody around it.

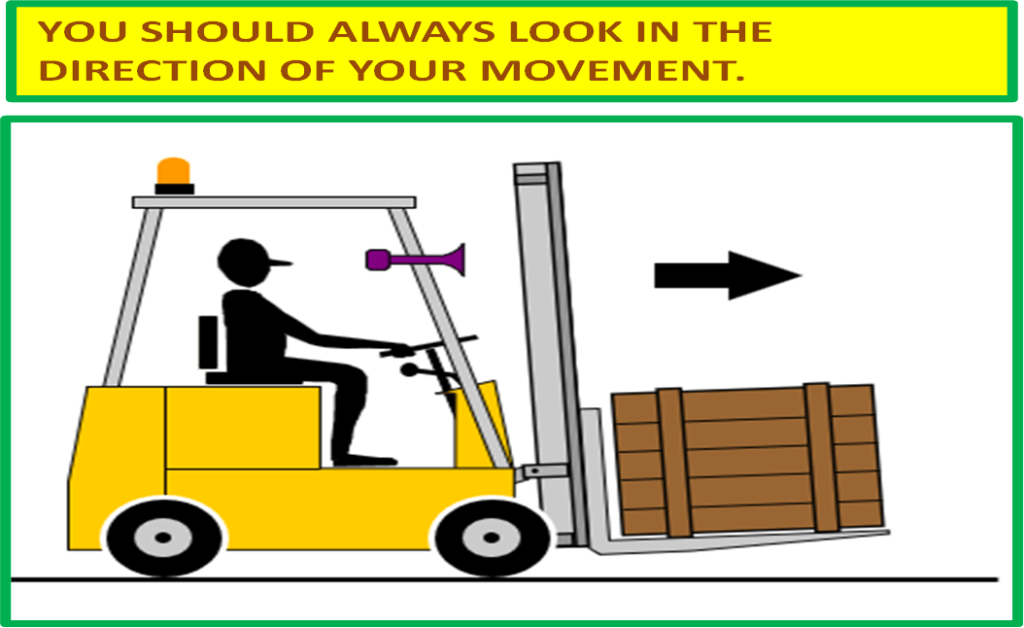

- Always look towards the direction of movement.

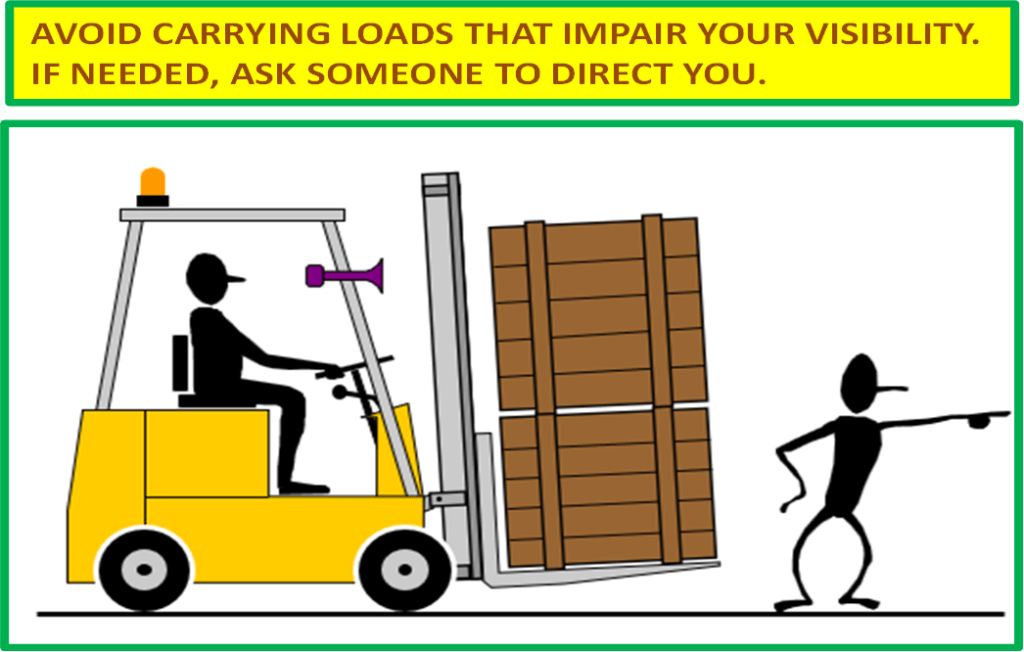

- Avoid carrying load that impair visibility, if required ask for person to guide the road.

- Blow horn in case of dangerous places.

- Never allow anyone under suspended load while operating forklift.

- Avoid Pedestrians.

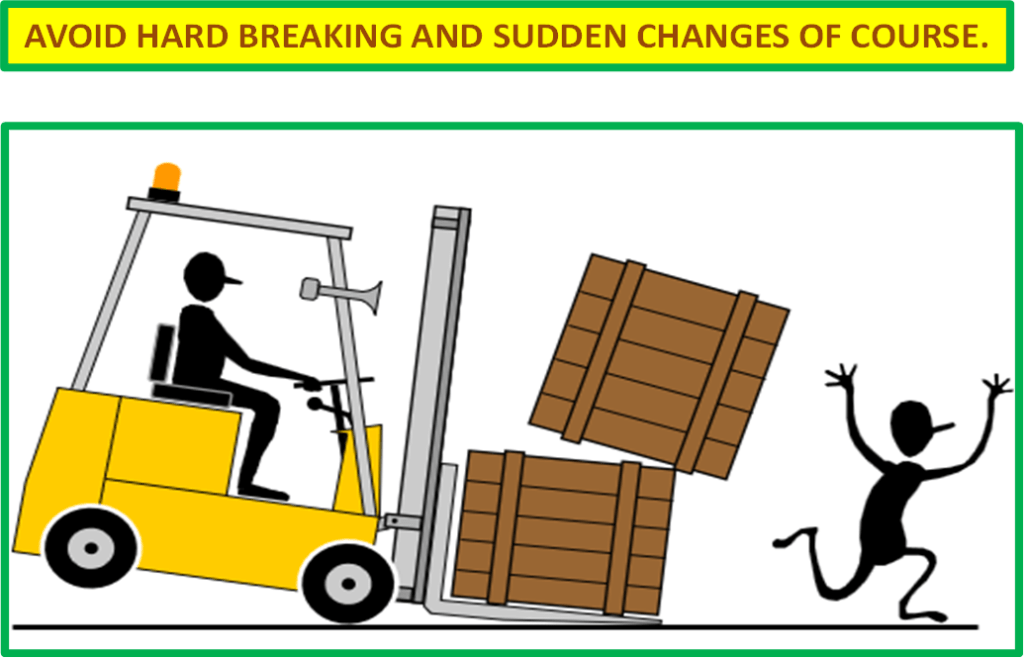

- Avoid hard braking.

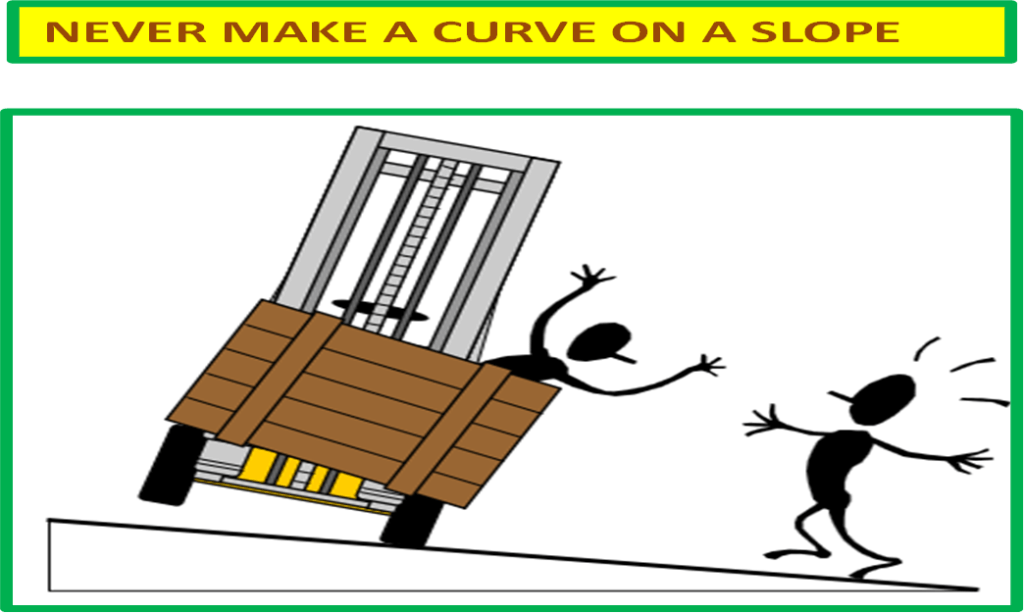

- Never make curve on slope.

- Never tilt a lifted load forward unless in it`s proper lifting site and even then, only a little.

- Ensure three points of contact while climbing in Forklift operator cabin.

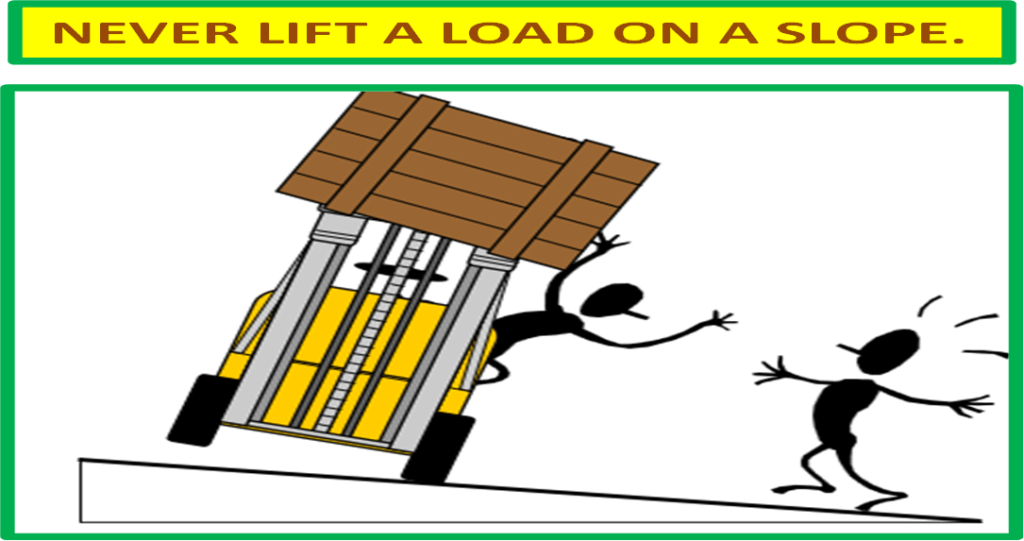

- Never lift a load on slope.

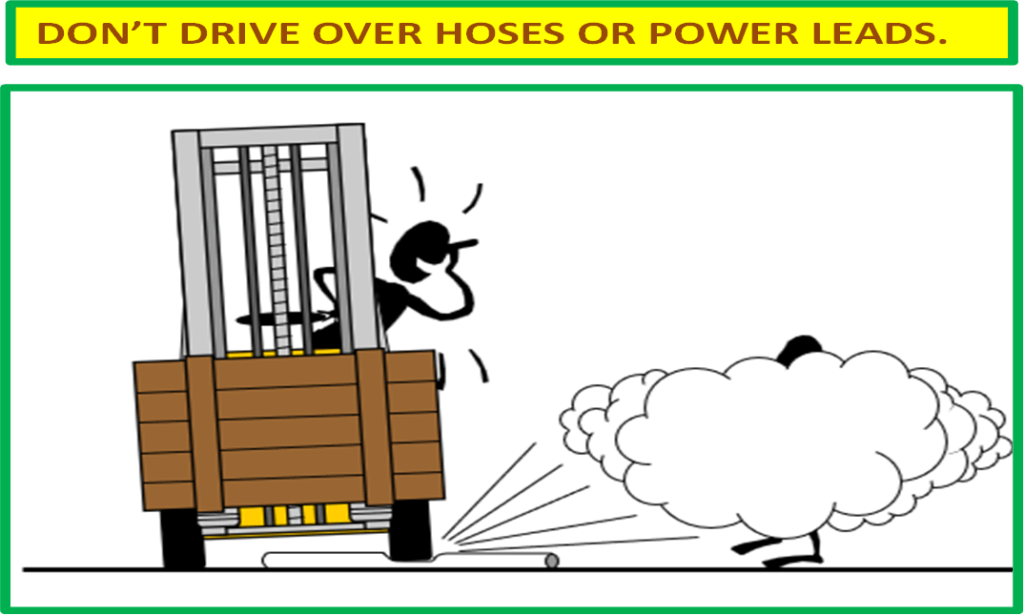

- Don`t drive hoses or power leads.

- Don`t operate forklift under influence of alcohol, drugs or medication.

Do not put your and your colleague life in danger

Hazards associated with Forklift

- Excessive speed while driving Forklift.

- Travelling forklift with elevated load.

- Vision blockage of operator while travelling Forklift due to load.

- Stability of Forklift. (Imbalance and improper load balance).

- Attachments of Forklift.

- Horse play while operating Forklift.

- Engine on while not in use.

- Damaged tires.

- Road surface conditions.

- Pedestrians.

- Untrained Operator.

- Unauthorized operator.

- Blind spots.

- Improper use.

- Unsecured Loads.

- Docks and Ramps.

- Improper maintenance.

- Refueling and Recharging Forklift.

- Overhead Obstructions.

- Seatbelts and tethers.

- Improper traffic management.

Daily Inspection of Forklift

Ensure below points to be checked on daily basis;

- Seat Belt.

- Warning Light.

- Backup Alarm.

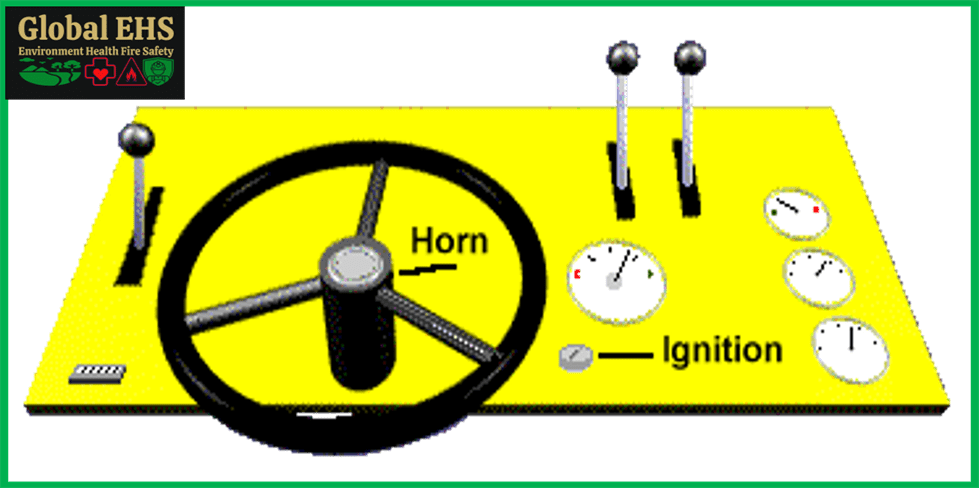

- Horn.

- Steering.

- Brakes.

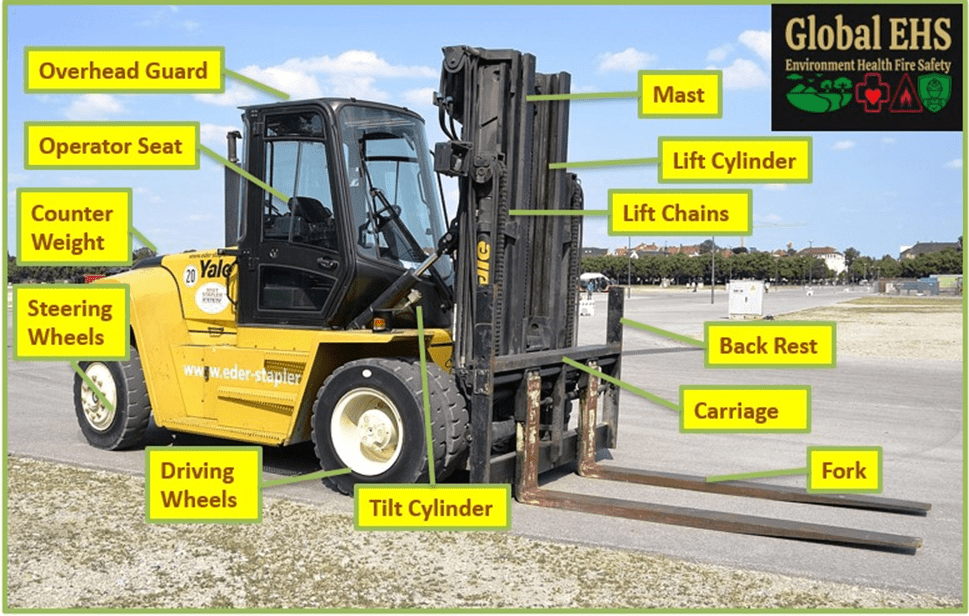

- Carriage, Chains, Forks.

- Hydraulic Hoses.

- Hydraulic Lift/Tilt Controls.

- Tires.

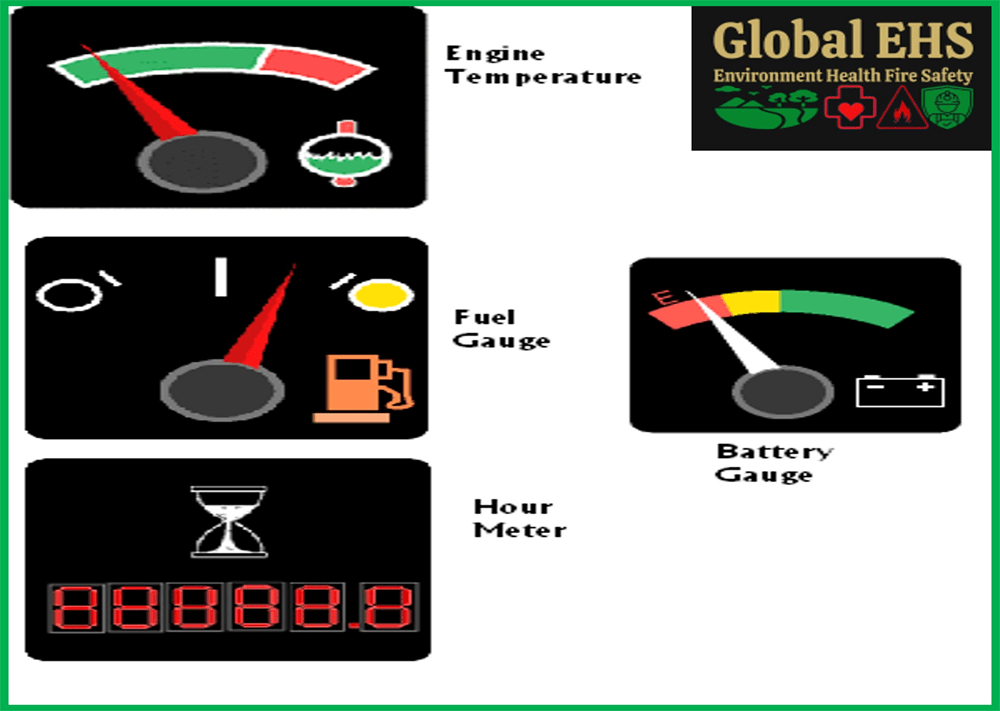

- Hour Meters.

- Leaks.

- Fuel Level.

- Oil Level.

- Water Level.

- Fan Belt.

- Nut Bolts of structure.

Classifications of Forklifts as per OSHA

As per Occupational Safety and Health Administration Forklift is classified as below;

Class-I: Electric Motor Riding Trucks.

Class-II: Electric Motor Narrow Aisle Truck.

Class-III: Electric Motor Hand Trucks Or Hand/Rider Trucks.

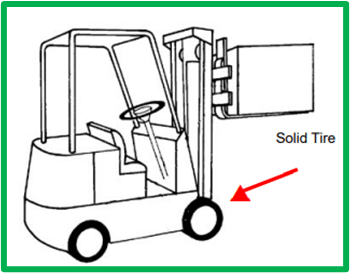

Class-IV: Internal Combustion Engine Trucks (Solid Or Cushion Tires) & Class-V: Internal Combustion Engine Trucks (Pneumatic Tires).

Class-VI: Electric and Internal Combustion Engine Tractors.

Class-VII: Rough Terrain Forklift Trucks.

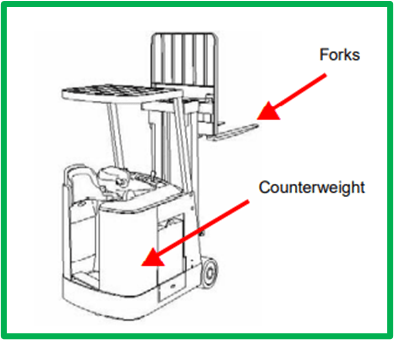

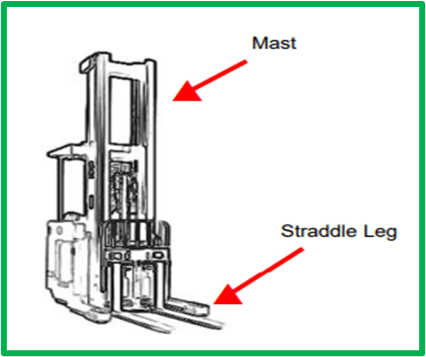

Anatomy of Forklift

Controls of Forklift

Switch controls of Forklift

Gauges of Forklift

Forklift Safety Rules