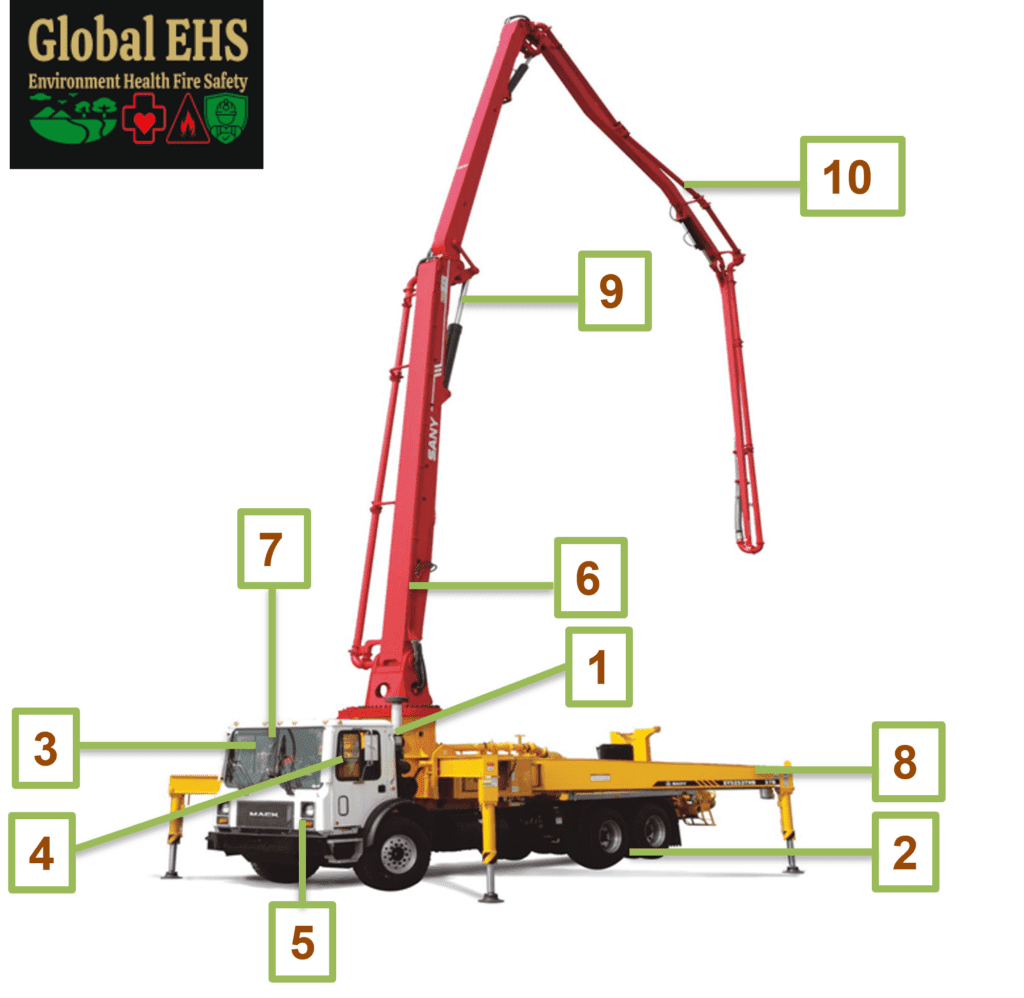

Boom Placer Inspection Checklist

Below are the checkpoints to ensure before start working with Boom Placer.

Inspectors must execute proper inspections and maintain records for them.

Boom Placer Inspection Checkpoints:

| SN | Details |

| 1 | Boom Placer should be physically sound and in good condition. |

| 2 | Tire should be free from damage. |

| 3 | Wind shield should be without damage. |

| 4 | All mirror should be in good condition and properly positioned. |

| 5 | Head lights, Tail lights, indicators, front horn and reverse horn are in working condition. |

| 6 | Boom should be physically sound and without any defect. |

| 7 | Wiper should be in running condition. |

| 8 | Outrigger should be in working condition and free from damage. |

| 9 | Hydraulic cylinder and hoses should be free from leakage and in working condition without any defect (Like Jam, corroded, etc.). |

| 10 | Pipe should be free from defects. |

| 11 | Covering of Rotatory part or moving parts with fix guard. |

| 12 | Red triangle and reflective tape should be fixed at proper place. |

| 13 | Operator should have valid and suitable license. |

| 14 | Fire extinguisher and First Aid Box should be available in operator cabin. |

| 15 | Normal and hand (Emergency Break) should be in working condition. |