Personal Protective Equipment is commonly referred as “PPE“.

Table of Contents

- Definition of Personal Protective Equipment or PPE

- Types of Personal Protective Equipment or PPE

- Pictorial view of PPE

- Importance of Personal Protective Equipment

Definition of Personal Protective Equipment or PPE:

- As per OSHA, PPE is equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. Personal protective equipment may include items such as gloves, safety glasses and shoes, earplugs or muffs, hard hats, respirators, or coveralls, vests and full body suits.

- PPE is the last line of defense.

Types of Personal Protective Equipment or PPE:

There are different ways to describe types of PPE based on its usage.

Here we are going to describe it as below;

- Face PPE.

- Head PPE.

- Eye PPE.

- Ear PPE.

- Hand & Arm PPE.

- Body PPE.

- Safety Belt and Harness PPE.

- Foot and Leg PPE.

- Respiratory PPE.

Let us see one by one:

1. Face PPE

It is used to protect face against chemical splash, flying objects, sparks, etc.

When and where to use:

- While handling chemicals.

- Working with electricity for protection against arc flash.

- Working with pressurized liquified gases like liquid nitrogen.

- Working at construction site.

- While welding, Cutting, Grinding.

- Working with metals.

- Etc.

2. Head PPE.

It is used to protect head from falling objects, flying objects, stuck with, Fall apart, etc.

When and where to use:

- On construction site.

- Material handling (Manual or mechanical).

- Etc.

3. Eye PPE.

It is used to protect eyes from chemical splash, spark, flying particles, flying objects, etc.

When and where to use:

- Welding.

- Cutting

- Grinding.

- Working with metals.

- Chemical handling.

- Etc.

4. Ear PPE.

It is used to protect against high noise.

When and where to use:

- Welding.

- Cutting

- Grinding.

- Working with metals.

- Working in noisy area.

- Etc.

5. Hand and Arm PPE.

It is used to protect against hot surface, pinch, sparks, Vibration, etc.

When and where to use:

- Welding.

- Cutting.

- Grinding.

- Working with metals.

- Working with Electricity.

- Doing construction activity.

- Material handling.

- Working with chemicals.

- Etc.

6. Body PPE.

It is used to protect against hot and cold surface, Sparks, Splash, Sharp edges, Infectious area, Abrasion, etc.

When and where to use:

- Welding.

- Cutting.

- Grinding.

- Working with metals.

- Working with Electricity.

- Material handling.

- Chemical handling.

- Hot and cold workplaces.

- Etc.

7. Safety Belt and Safety Harness PPE.

It is used to protect against fall from height hazard.

When and where to use:

While working at Height.

8. Foot and Leg PPE.

It is used to protect against struck with, falling objects, animal hazards, pinch, struck by, Hot and cold surface, splash, slippery surfaces, etc.

When and where to use:

- Welding.

- Cutting.

- Grinding.

- Working with metals.

- Working with Electricity.

- Material handling.

- Chemical handling.

- Working at height.

- On construction site.

- Etc.

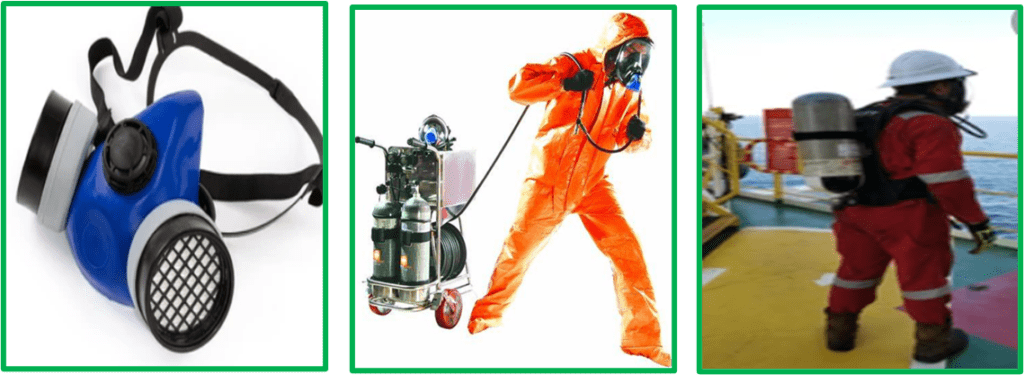

9. Respiratory PPE.

It is used to protect against confines spaces, Smoke, dust, toxic gases, fumes, vapor, mist, etc.

Types of Respiratory PPE:

- Air purifying Respirator

- Supplied Air Respirator

- Self-Contained Breathing Apparatus or SCBA

When and where to use:

- Welding.

- Cutting.

- Grinding.

- Material handling.

- Chemical handling.

- Dusty workplace.

- Firefighting.

- Etc.

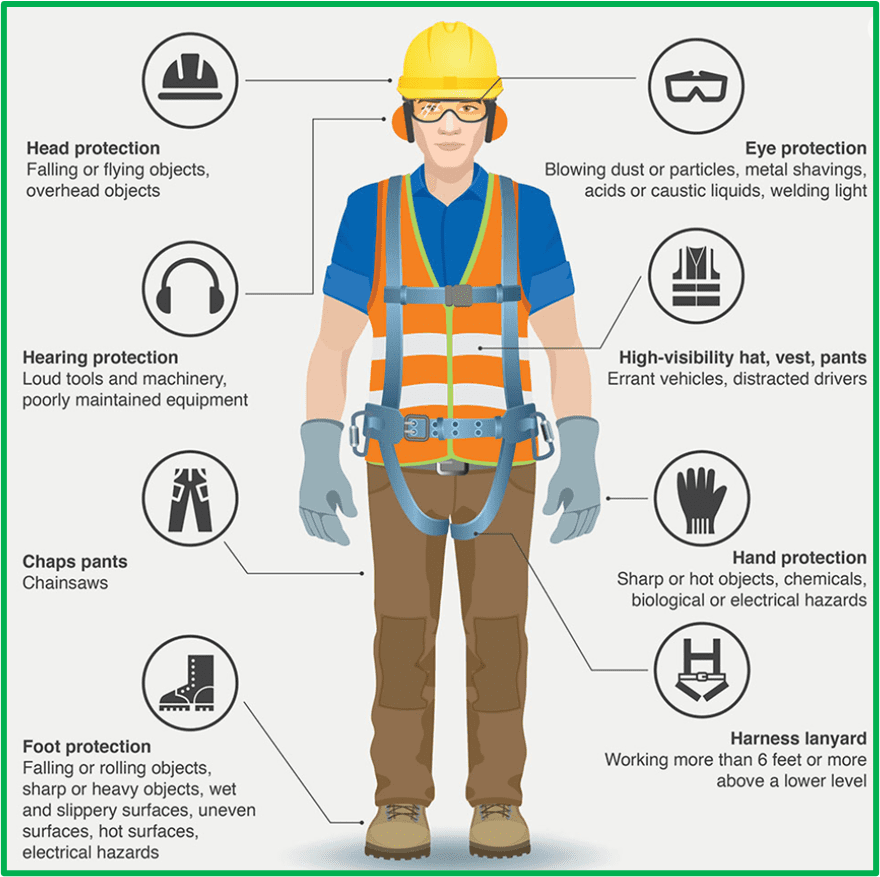

Pictorial view of PPE:

Image Source :PPE_person.jpg (1024×976) (umn.edu)

Importance of Personal Protective Equipment:

- It protects.

- It protects important and irreparable body parts like eye.

- It is the last line of defense.

- Decrease chances of injury.

- Increase Morale of employee.

- It makes you visible all the time.

- As it protects employees from unwanted injury, thus it decrease medical expenses which leads to reduce mandatory insurance plan cost.

- Increase willingness to work as their safety is assured.

- It protects health of employee.

- It stops accidents.

- It protects from long-term illnesses.

- By decreasing absenteeism, it increases productivity.

- It increase quality of workday.

- It is replaceable.

- It is under your control.

- It gives good Impression.

- It helps reputation of industry to sustain.

- It makes you safe against Hidden Hazards.

- It is legal requirement.

- Last but not the least “It save lives”.